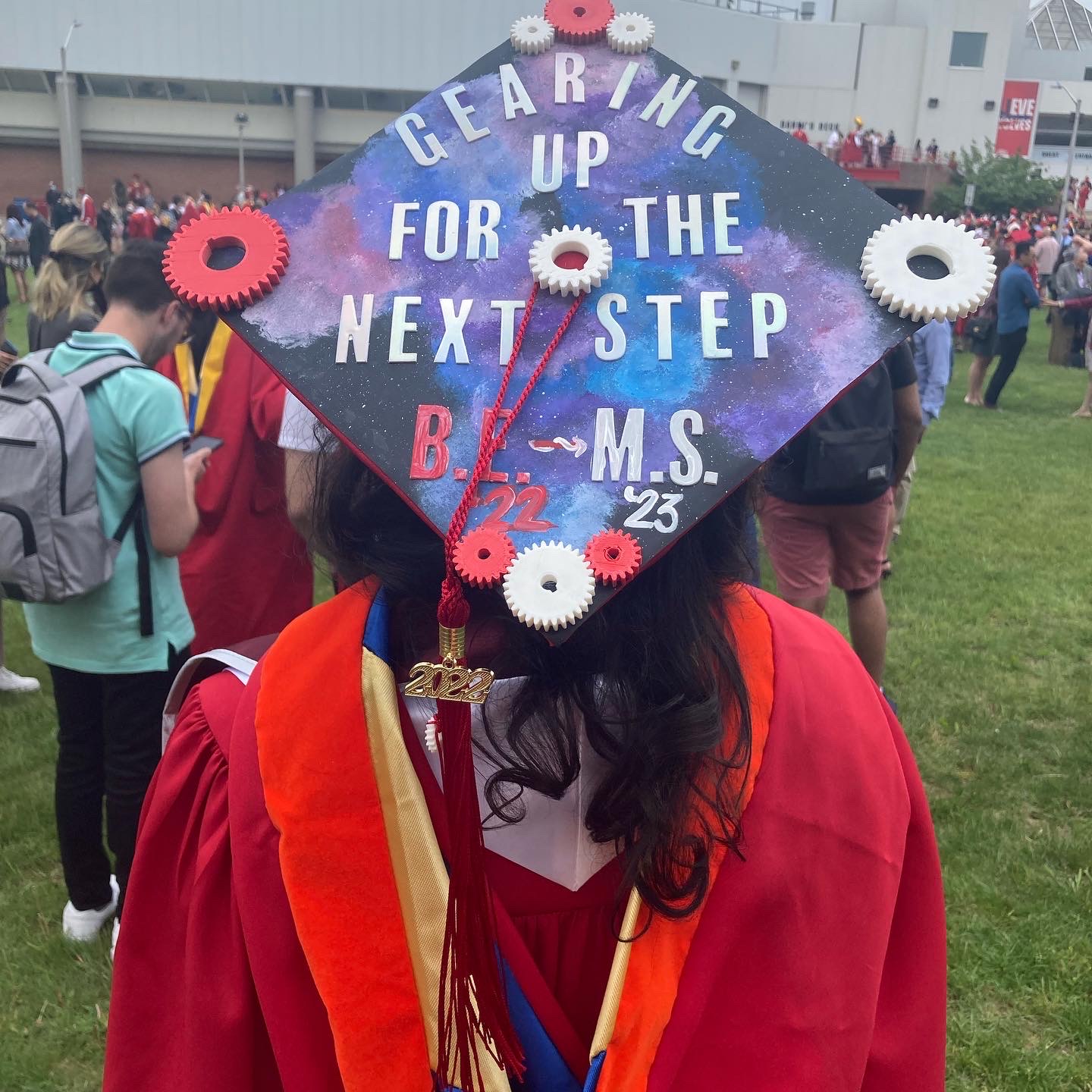

Student Spotlight: Leana Grotz

Leana Grotz is a recent graduate of the BE program and is part of the 5-year BE/MS

program. She currently works as a student employee for the Machine Shop and has spent

the summer preparing both the machine shop and the brand new Makerspace, as well as

took initiative to paint their doors, brightening up the hallways of the Engineering

basement.

What area of Mechanical Engineering do you study? What interested you in that particular

area?

What area of Mechanical Engineering do you study? What interested you in that particular

area?

I have two main focuses in Mechanical Engineering. The first one being the manufacturing

processes and this has been a huge one for me since I have been involved in working

in a shop since high school. I love tackling problems with hands-on solutions and

being able to be a part of the processes in developing/improving a project or product.

The second focus for me has been Solid Mechanics and my interest in this area began

back in my sophomore year when I took MEC 363 Solid Mechanics. This interest stuck

with me throughout my college career and now I am currently pursuing a Master's in

this area of Mechanical Engineering.

Tell me about your job - where you work, any specific role, the best and most challenging

aspects?

My job as the Student Machine Shop Assistant is probably the part that I am most grateful

for throughout my college experience. This job is split into a few different parts.

The first part being the Teaching Assistant for a crowd favorite class, MEC 225: Fundamentals

of Machining Practices. Being able to guide students through the class and get them

to be able to feel comfortable with industrial metal-working equipment is one of my

favorite parts of my job, I love teaching and I love seeing students develop their

skill as the semester progresses. Another part of my job is assisting in the CEAS

Machine Shop, this means assisting with manufacturing any fixtures needed by research

professors, maybe parts for students for the Senior Design Project, or simply assisting

in a project that someone is just passionate about. I enjoy both aspects of

this job, being able to interact with the students and leave some of my own experiences

with them is something that feels so fulfilling. That same fulfillment is definitely

granted while being able to create something and say that it's my own. The most challenging

aspects of this job entails safety. Being able to help ensure that students are operating

the equipment in a safe manner can definitely be stressful, as I mentioned this equipment

is industrial grade and could be really dangerous if operated in an unsafe manner.

Another challenge of this job is being able to understand someone else's design, especially

with improper drawings, it can be hard to create something for someone how they want

it when it's not exactly clear.

Are there any faculty or staff members that influenced you as an engineering student?

If so, who and how so?

I am actually thankful to say that there are quite a bit of faculty and staff members

that have influenced me as an Engineering Student. Professor Noah Machtay for his

high standards and for helping me build my confidence as an engineer through his lectures

in MEC 220,MEC 325 and MEC 411. Professor Kedar Kirane has given me the best research

opportunity,helping me build my independence and for guiding me in my development

of my research skills. Austin Giordano and Jason Loprete for also giving me the best

advice since the beginning of my undergraduate career (and continuously now) and all

of their devoted time in helping me. Mr. Joseph Schurz for not only helping me develop

skills necessary as an engineer but also letting me feel heard with my input on MEC

225, for all of his support and encouragement when I was doubting if I could even

graduate with my bachelor of engineering.

Can you talk about your experience working in the machine shop and developing the

Makerspace?

The development of the Makerspace is still in its infancy phase; however, it's nice

to be able to give student input into how the space can be organized and used.

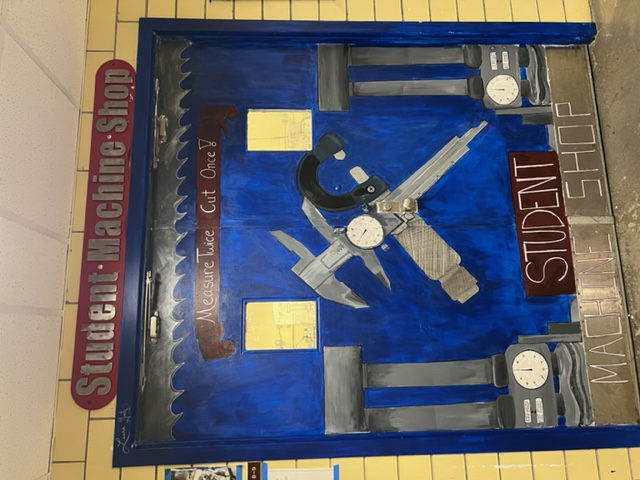

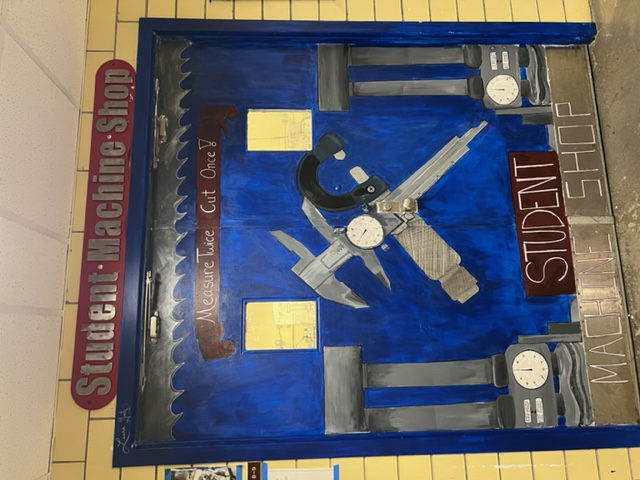

The Student Machine Shop and CEAS Makerspace doors you painted encapsulates all of

the different engineering departments in an innovative and unique way. What was the

inspiration behind these designs?

The Student Machine Shop and CEAS Makerspace doors you painted encapsulates all of

the different engineering departments in an innovative and unique way. What was the

inspiration behind these designs?

So my process in designing these doors is a little chaotic since I start with a small

sketch on paper and then go right into painting. For the Student Machine Shop doors,

those are based on the main tools and instruments that students use within the class

and based on the classic machine shop quote: Measure Twice, Cut Once. For the CEAS Makerspace, I wanted to do something that symbolized the unity of all

the departments under this college as well as something that signifies the necessity

of interdisciplinary fields being able to work together to create something great.

How do you spend your time when you’re not working?

When I am not working, I am involved in the arts. I love to paint and sculpt in my

free time to make sure that I am still actively using the creative part of me.

What is one piece of advice that you'd like to share with prospective graduate students?

My one piece of advice is to be open-minded to everything that may come your way.

If you had asked me 4 years ago if I would be involved in a Master's Program and doing

a thesis, I would've said most definitely not. I am so very happy I kept an open-mind

to opportunities and took them throughout my career.

What area of Mechanical Engineering do you study? What interested you in that particular

area?

What area of Mechanical Engineering do you study? What interested you in that particular

area? The Student Machine Shop and CEAS Makerspace doors you painted encapsulates all of

the different engineering departments in an innovative and unique way. What was the

inspiration behind these designs?

The Student Machine Shop and CEAS Makerspace doors you painted encapsulates all of

the different engineering departments in an innovative and unique way. What was the

inspiration behind these designs?